First remove the Platen and Spindle. Removing the Splash Pan will make your job easier, though the photos here show removing the Spindle Housing with the Splash Pan still attached.

The Spindle Housing is a machined block of aluminum which holds a couple of sealed bearings. The Platen and Spindle assembly slide into these bearings.

The Spindle Housing is attached to the Base Plate by three hold-down bolts. Under the Spindle Housing next to the hold-down bolt holes are three set screws which adjust the Platen Tilt alignment.

Carefully use a 7/16″ wrench to loosen these Spindle Housing hold-down bolts. I loosened them off 1/4 turn each, going around to all 3 in turn until they were loose enough to remove by hand.

This space is cramped so take your time and be careful.

Once the bolts are removed the whole Spindle Housing and Splash Pan are free to be lifted out.

Here is a bottom view of the removed Spindle Housing with Splash Pan attached.

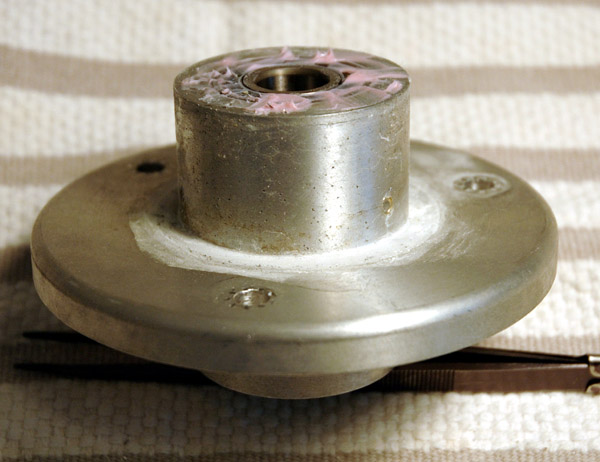

A close-up of the Spindle Housing bottom. Hard to see here but there is evidence of water and corrosion starting on the Spindle Housing. It’s seen the clearest as the rust-colored are around the bottom bolt hole.

And here is a close-up of the Spindle Housing assembly removed from the Splash Pan. Note the dull appearance of this part with the corrosion pits and water leakage stains. The pink goop on the bearings is some sort of grease applied at the Jersey Instruments factory. Please visit the Omni Design Flaws section for more discussion.

This is what the Omni Base Plate looked like when I removed my Spindle Housing. Note the rubber o-rings as well as the obvious water-staining.

And this is a close-up shot of where the Spindle Housing sits. Notice the three set screws for adjusting the Platen Tilt, as well as the rust and corrosion marks.

For more detailed photos and discussion visit the Omni Design Flaws section.